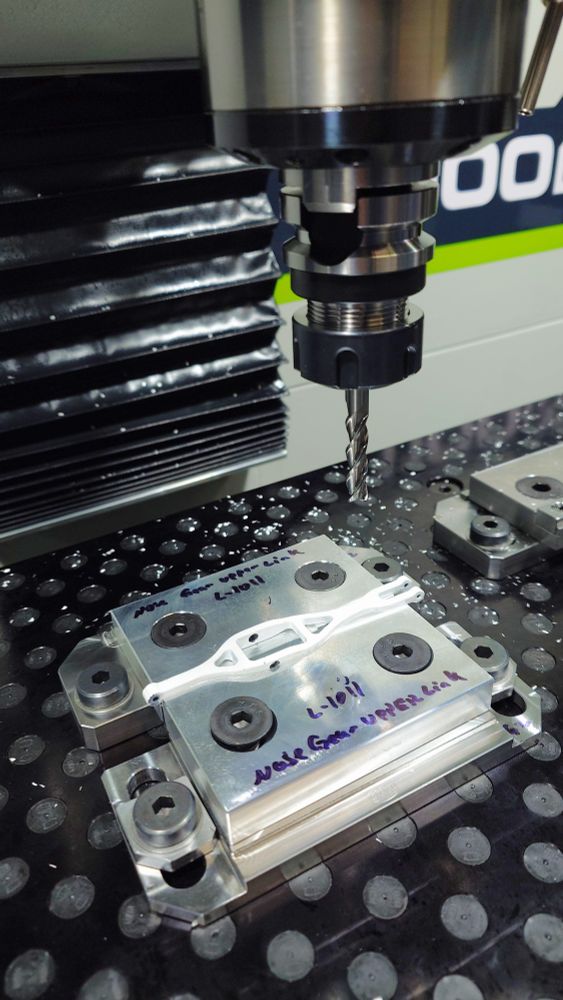

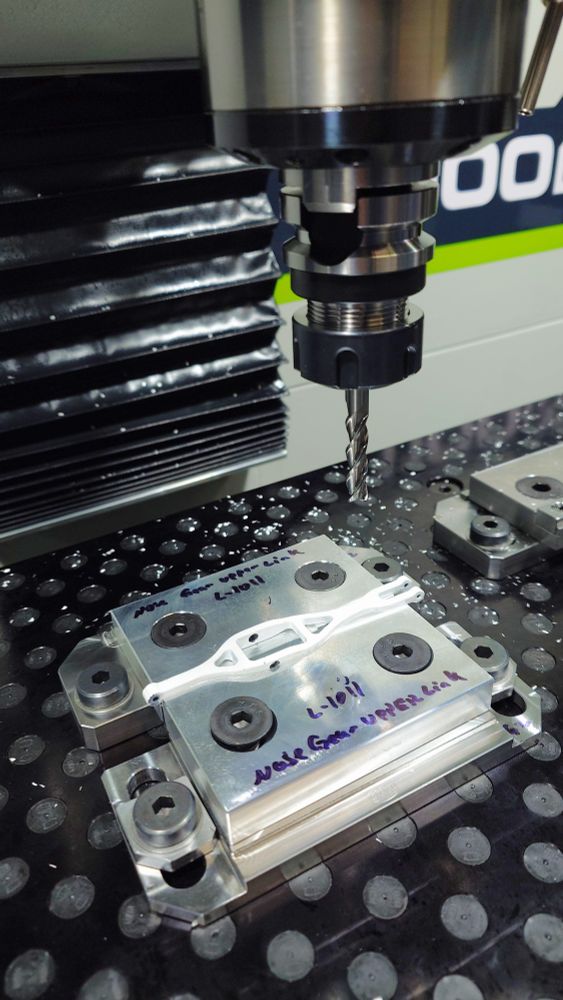

Milling Op4's soft-jaws for the RC L-1011 airliner nose gear upper drag brace. Soft-jaws are used to hold/clamp a part in place in order to mill a specific portion of it.

#rc #cnc

03.12.2024 01:07 — 👍 2 🔁 0 💬 0 📌 0

Verifying the freshly CNC milled soft jaws for the RC L-1011 Nose Gear Uppers Drag Brace are correct. These are for Op 2 of 4. You can see a 3D printed brace used as a stand in.

On to make the next set.

#cnc #rc

02.12.2024 23:40 — 👍 2 🔁 1 💬 0 📌 0

Looking back at the kinematic and mechanical design for the main landing gear bay doors for the L-1011 RC airplane.

#rc #mechanical #engineering

27.11.2024 22:50 — 👍 4 🔁 0 💬 0 📌 0

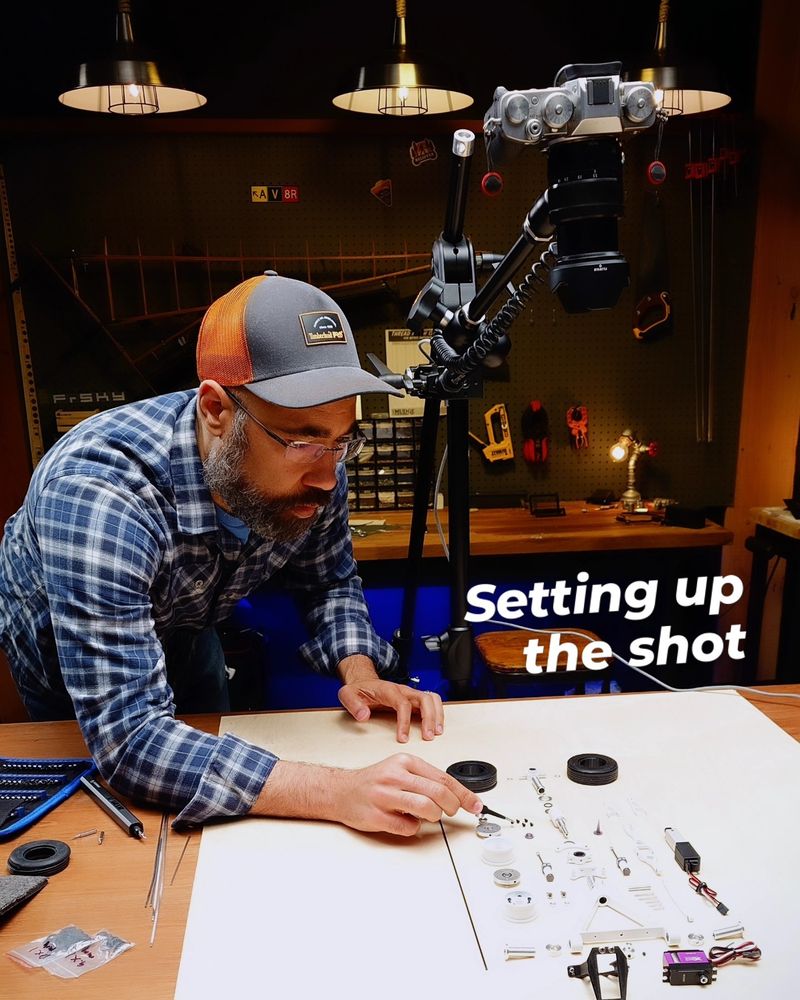

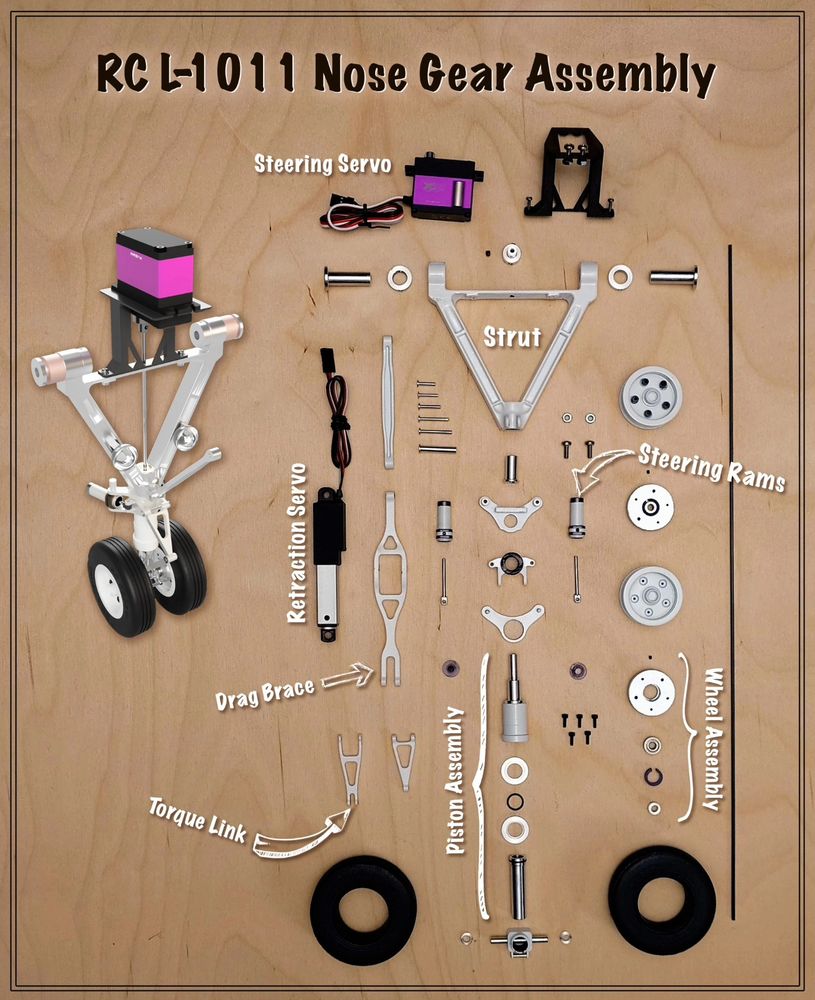

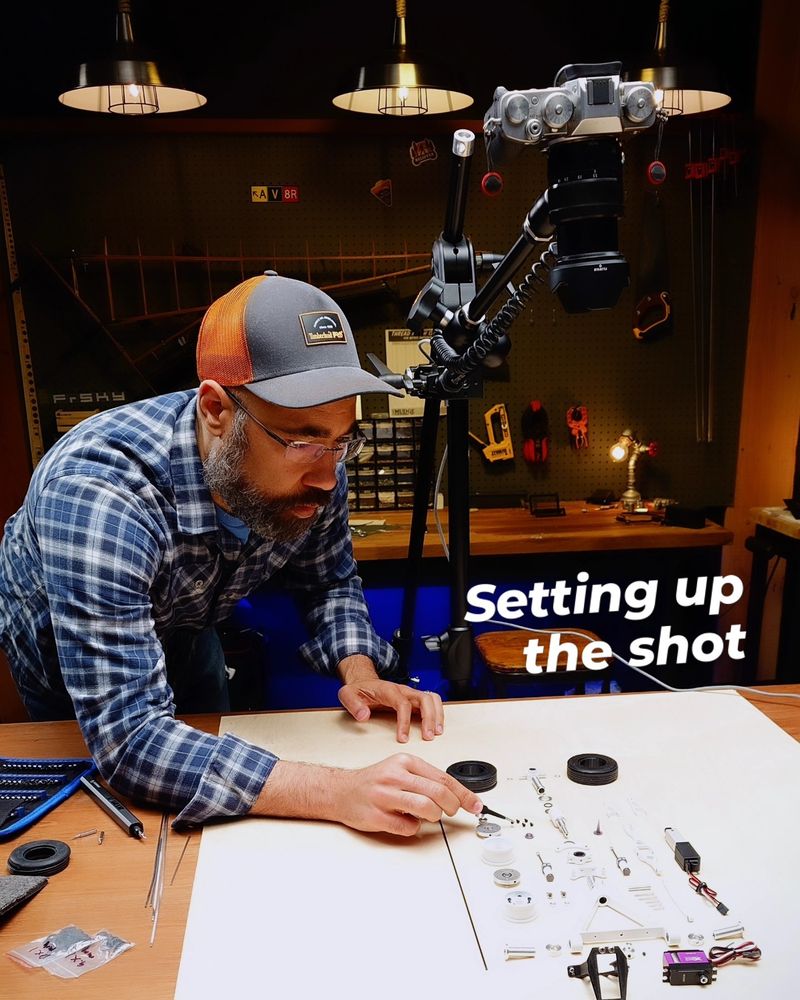

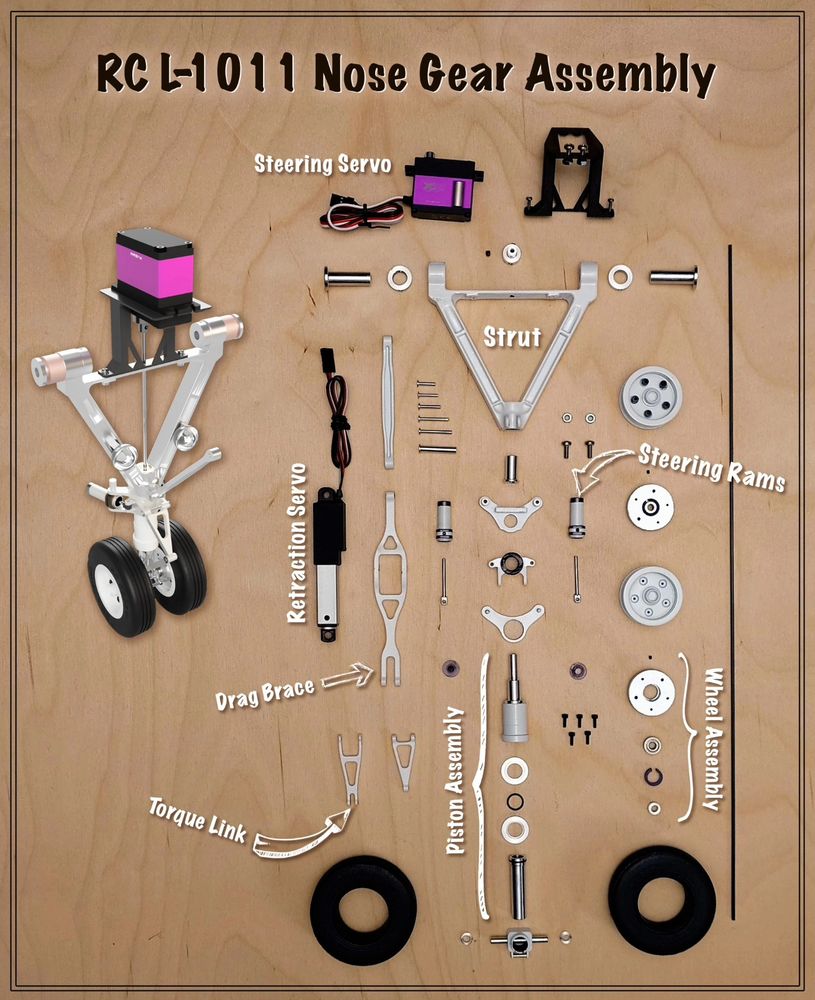

Setting up the plan view shot of RC airplane landing gear for the L-1011

Assembly layout of the L-1011 RC airplane parts made from resin 3D printed parts and some lathe turned parts.

These are all the parts for the nose gear of the RC L-1011. Shown are the 3D printed and lathe turned prototype pieces laid out.

This week I start machining the 3D printed parts from aluminum on the CNC Mill.

#3dprinting #rc #engineering

24.11.2024 21:14 — 👍 14 🔁 1 💬 0 📌 0

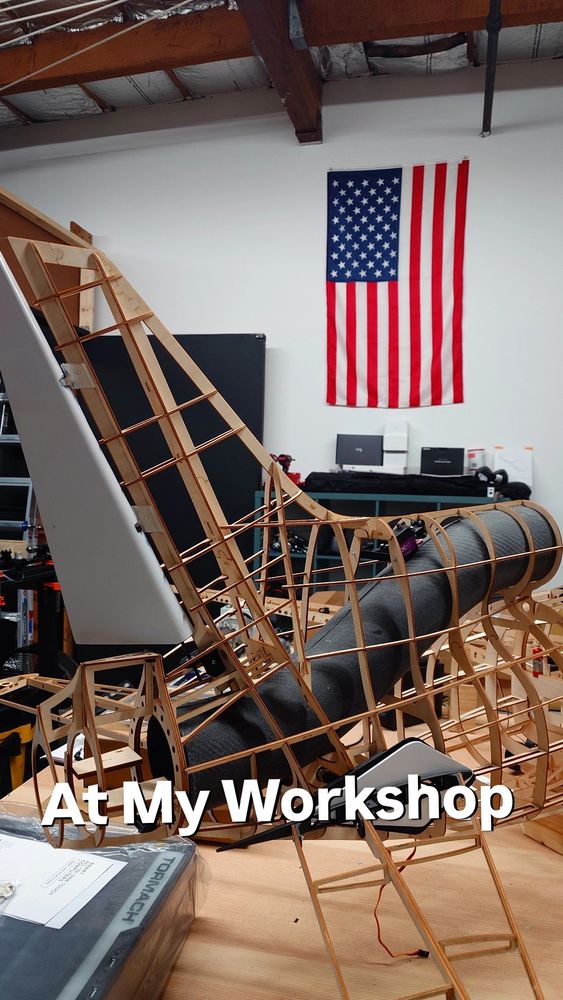

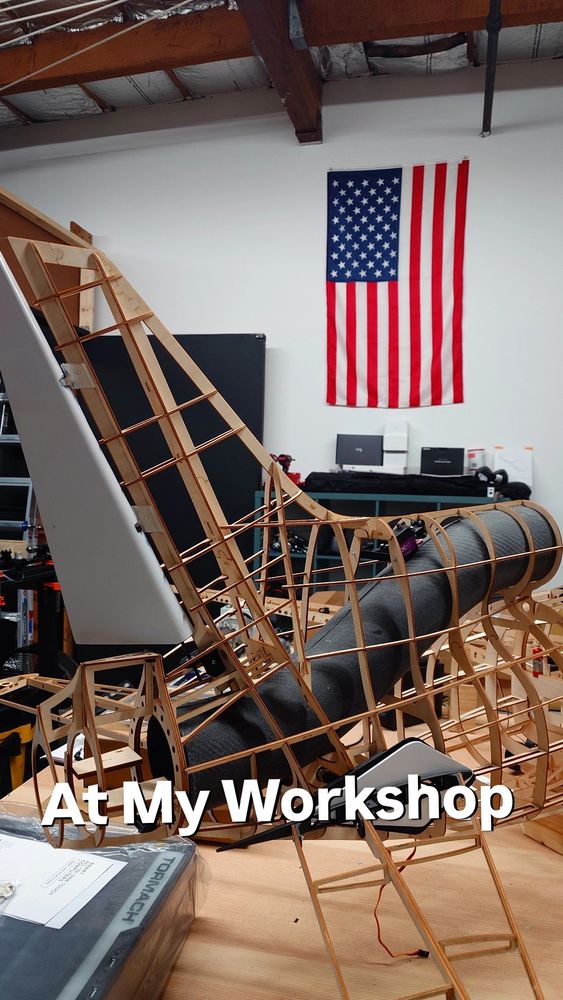

RC airplane L-1011 tail section frame in the RC CAD workshop with the American flag hanging on the wall in the background.

Another day in the workshop.

#build #rcairplane

22.11.2024 18:23 — 👍 11 🔁 0 💬 2 📌 0

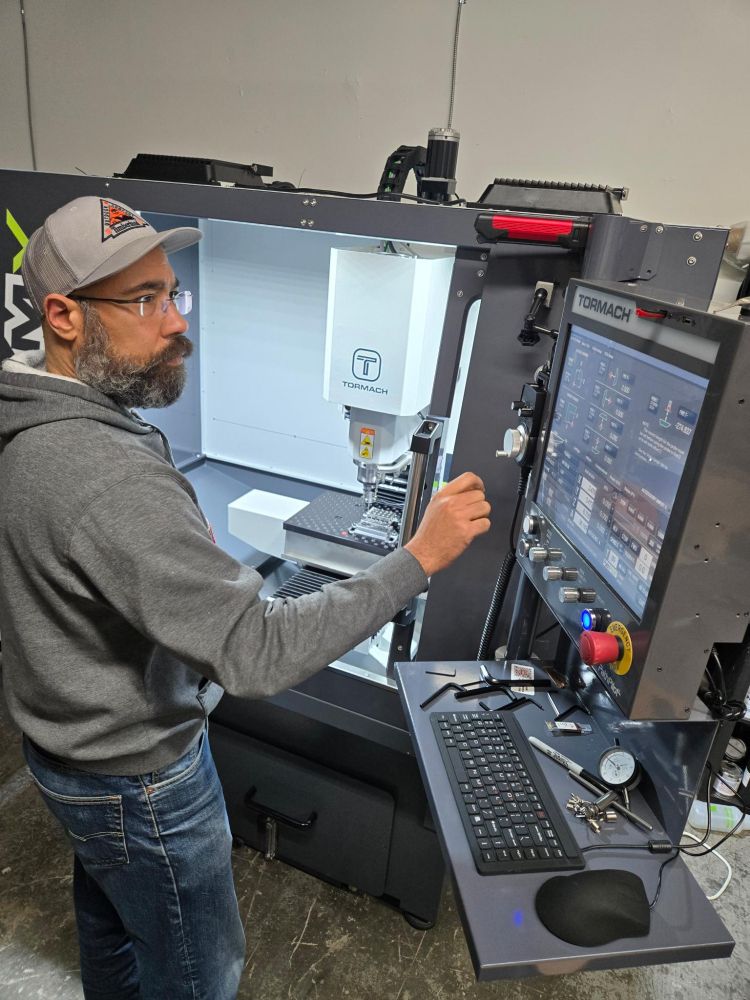

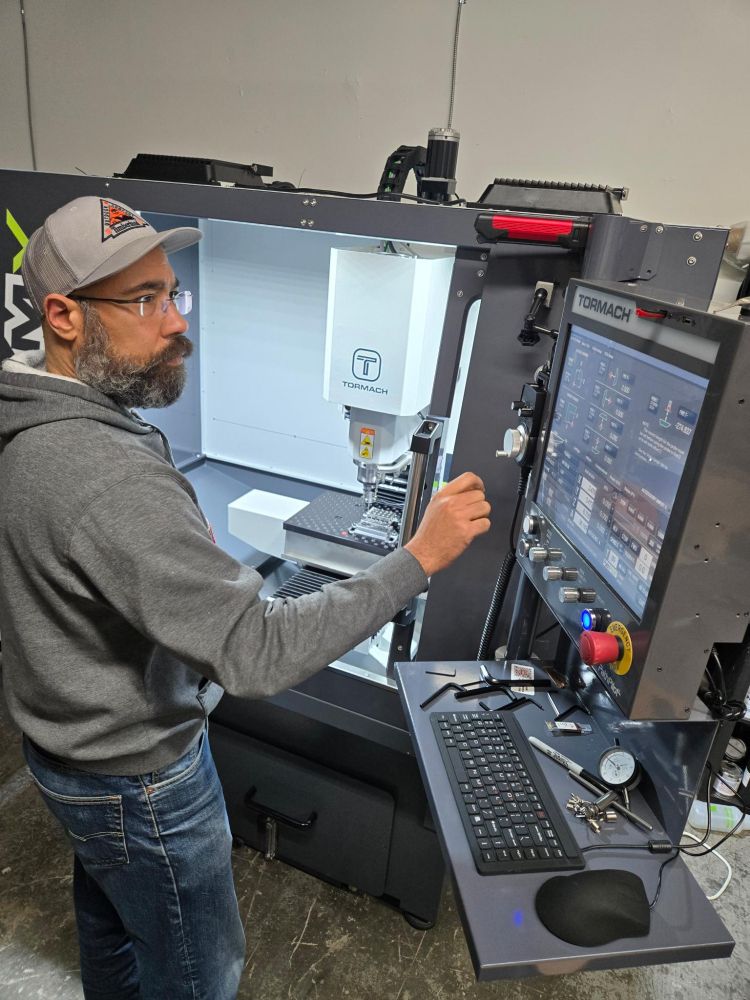

Terrance watching the probe set the XY home coordinates on the Tormach 1100MX

Terrance getting ready to start the work piece offset probing routine.

Getting the CNC tool and work offsets ready before starting the aluminum landing gear parts jobs.

#cnc #machining

19.11.2024 21:18 — 👍 3 🔁 0 💬 0 📌 0

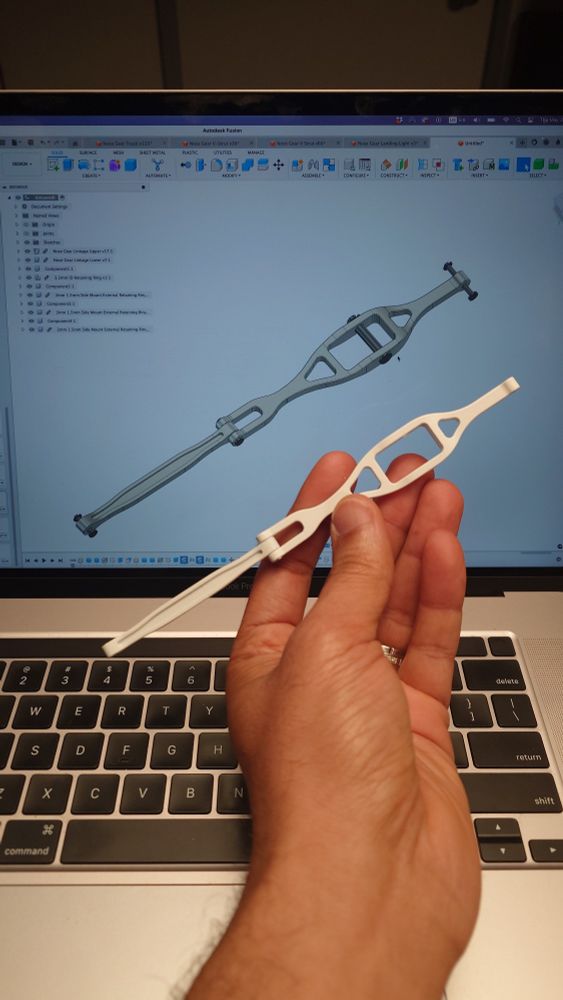

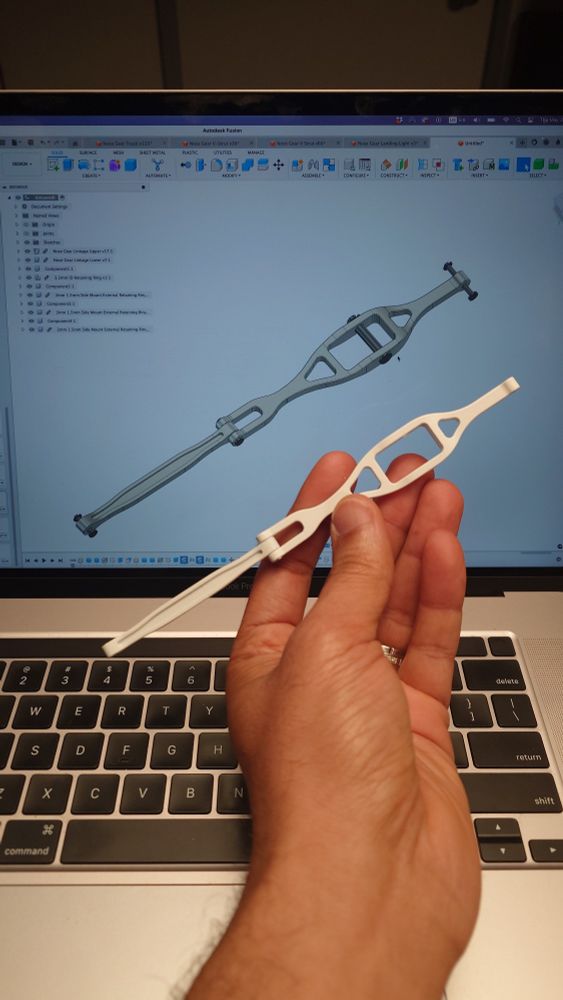

CAM set up in Fusion 360 for RC Nose Gear drag brace

CAM environment in Fusion 360

Getting the Tormach 1100 ready for machining the drag brace.

3D printed prototype of Drag Brace for RC landing gear.

Getting the CNC CAM program designed to machine the nose gear drag brace on the Tormach 1100MX. Going from 3D printed prototype (pictured) to machined aluminum (soon).

#cnc #machining

18.11.2024 19:54 — 👍 2 🔁 0 💬 0 📌 0

Thanks! It was a fun project to work on.

18.11.2024 16:27 — 👍 1 🔁 0 💬 1 📌 0

Model of the 1.3 meter tall Boeing 787 main landing gear side view for airshow exhibit.

Model of the 1.3 meter tall Boeing 787 main landing gear rear quartering view. Made for an airshow exhibit.

Delivery of the 1:5th scale Boeing 787 model to client's office. It was for an interactive exhibit at the 2024 Farnborough Air Show.

Awesome 3D printing project this year.

#aerospace #tradeshow

17.11.2024 17:12 — 👍 4 🔁 0 💬 1 📌 0

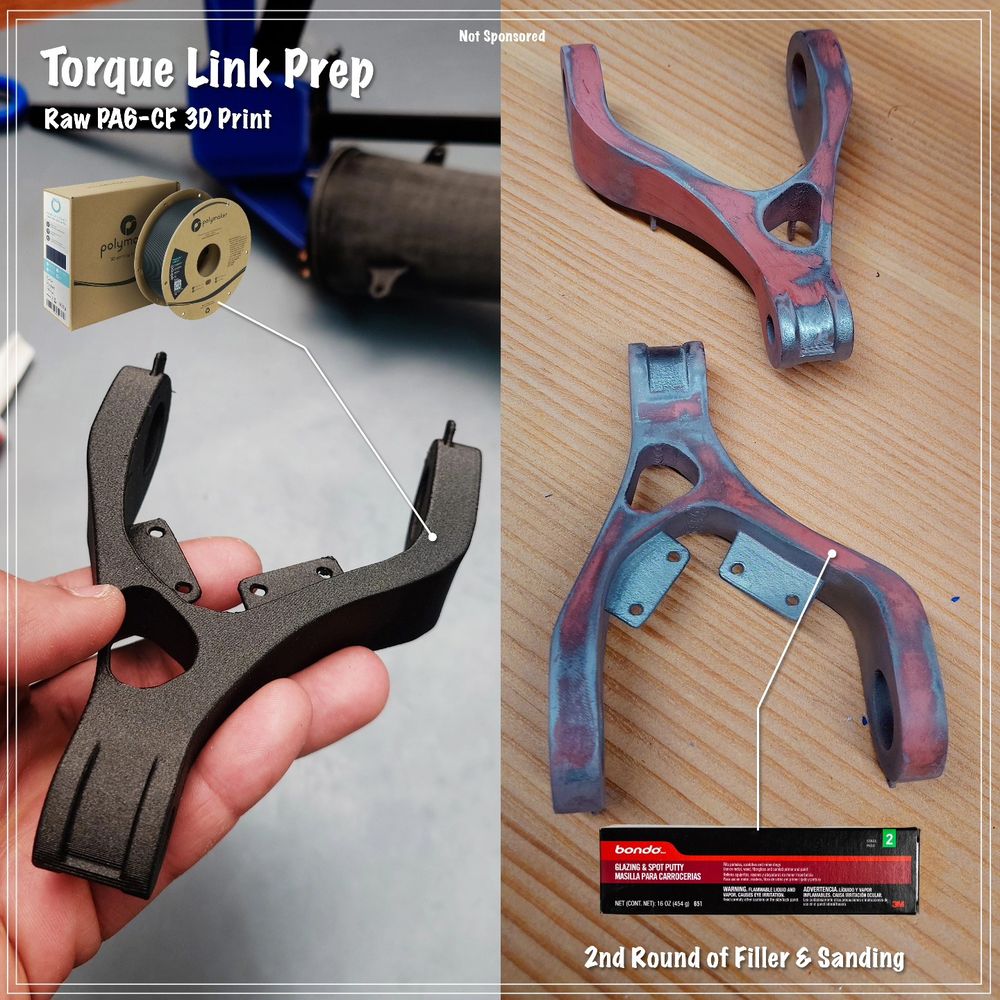

Dry fitting 3D printed landing gear strut

Model Hydraulic coupler 3D printed from resin and finished with metallic paint.

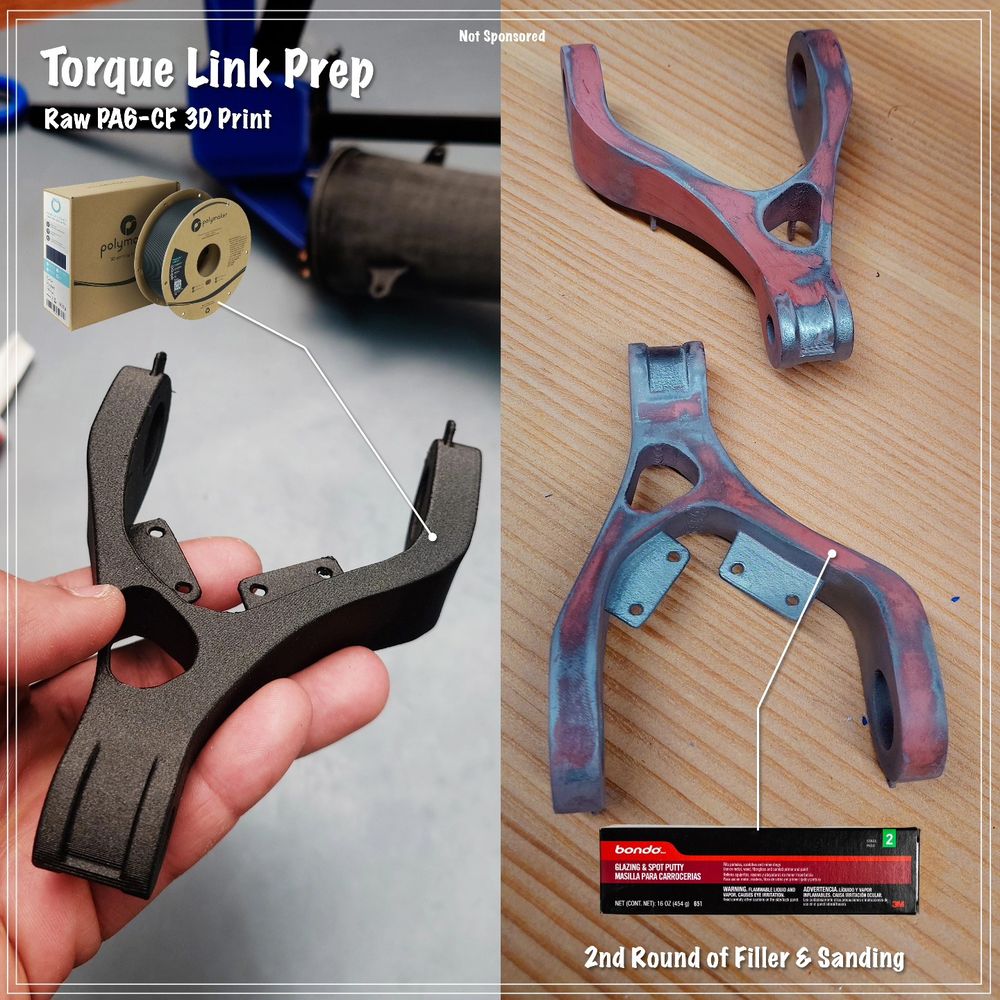

Preparing 3D printed torque link for the model 787 main landing gear. Using Bondo filler sander to get a nice smooth finish.

Terrance sanding the primer coat on the 787 main landing gear strut.

Making of the Boeing 787 maybe landing gear model using 3D printing.

#3Dprinting

17.11.2024 17:12 — 👍 2 🔁 0 💬 1 📌 0

Terrance standing next to custom hand crafted model of Boeing 787 landing gear.

1:5th scale model of #Boeing 787 that I made from scratch for a client this summer. Used as part of an airshow exhibit.

#3DPrinted #engineering

17.11.2024 17:12 — 👍 6 🔁 0 💬 1 📌 0

Terrance with tooling ready to make parts on the Tormach CNC Mill.

The new CNC Mill is finally in the workshop ready to start making landing for the L-1011 kit next week. The last of the tooling arrived yesterday.

LET MAKE RC LANDING GEAR!!

#cnc #rcairplane

16.11.2024 18:28 — 👍 1 🔁 0 💬 1 📌 0

Terrance smiling in the RC CAD workshop with L-1011 RC Airplane frame in the background.

First post from the RC CAD Workshop. Hello Bluesky

#rcairplane #workshop

14.11.2024 00:25 — 👍 11 🔁 0 💬 0 📌 0