Adding a jet engine to your 3D Printer is my idea of a good idea #3dprinting #resin #jet

02.12.2025 15:38 — 👍 1 🔁 0 💬 0 📌 0

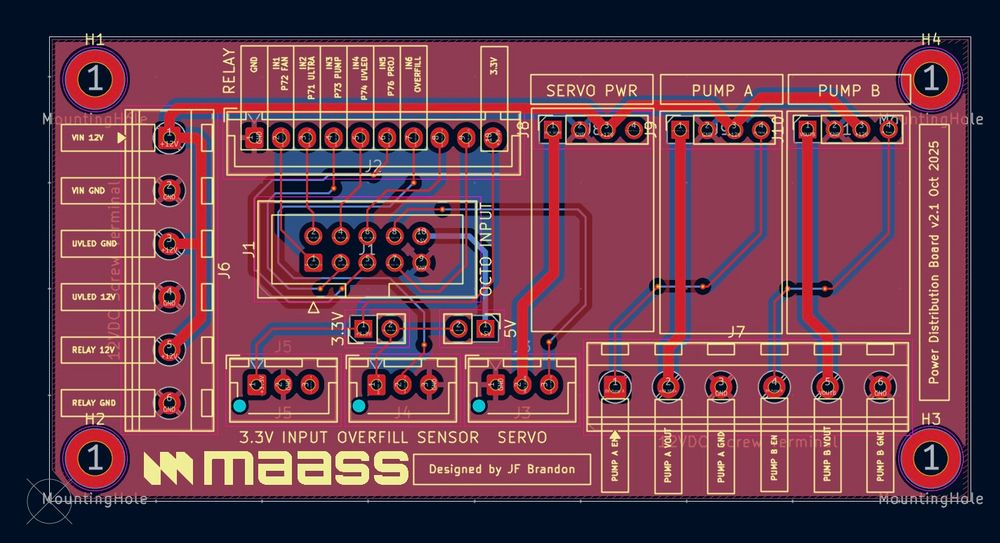

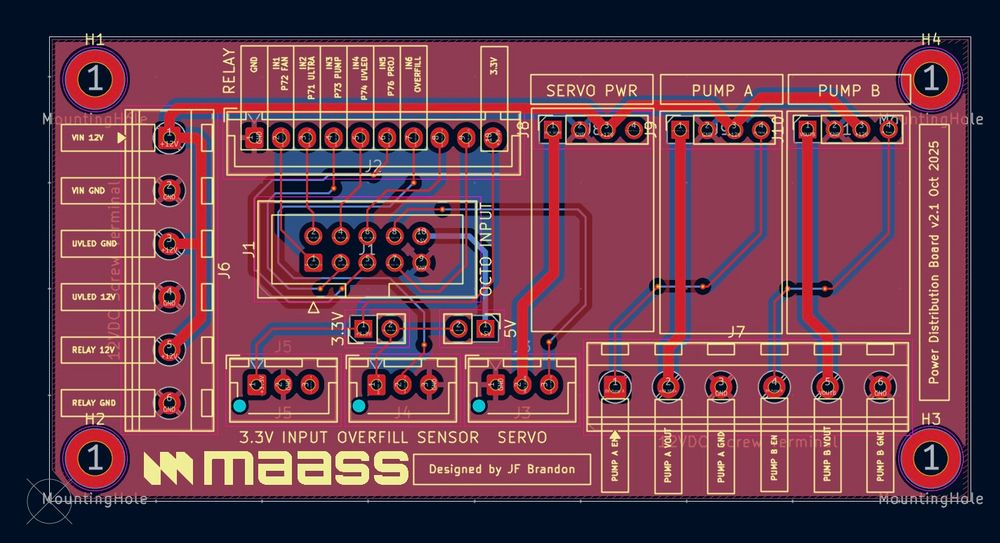

Tah dah! Works fine - minus a few mistakes in the silkscreen.

30.11.2025 04:24 — 👍 3 🔁 0 💬 0 📌 0

Getting back into @kicad.org to refine the wiring inside Shimmy. It’s not some FPGA board, but it saves time during manufacturing #pcb #circuits #hardware

10.11.2025 14:28 — 👍 3 🔁 0 💬 0 📌 0

Shipping has been an unexpected time-suck. Shimmy is designed to be robust, but freight carriers truly try to trash your product. ULine crates only go so far - so we’ve had to buttress it to reduce any damage from stacking during shipment.

31.10.2025 01:16 — 👍 3 🔁 0 💬 0 📌 0

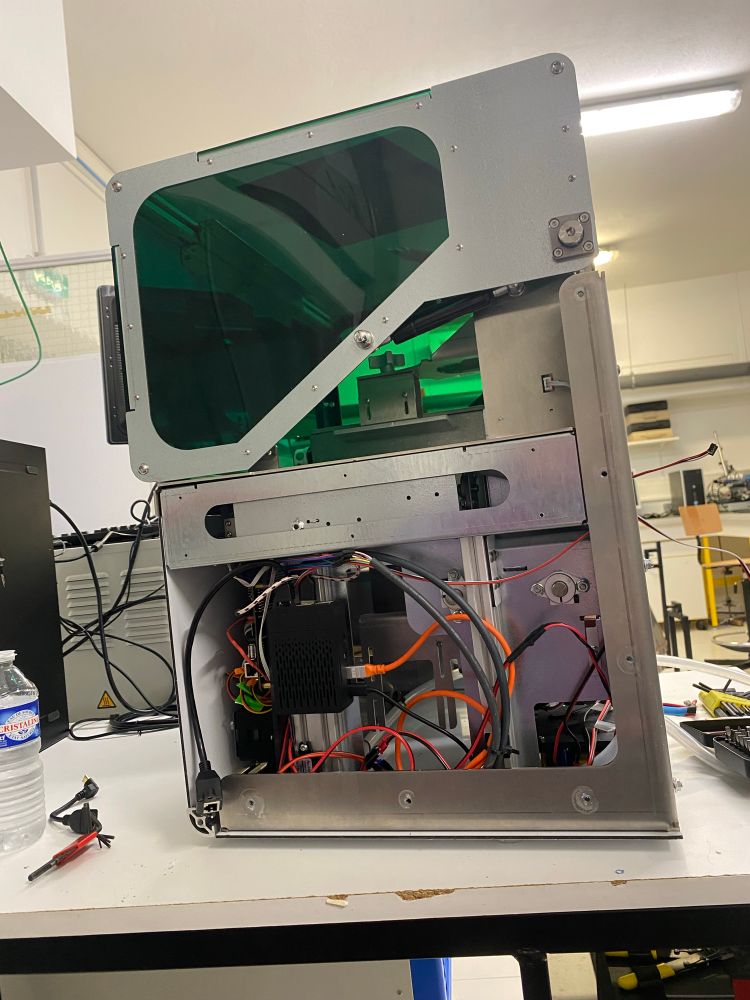

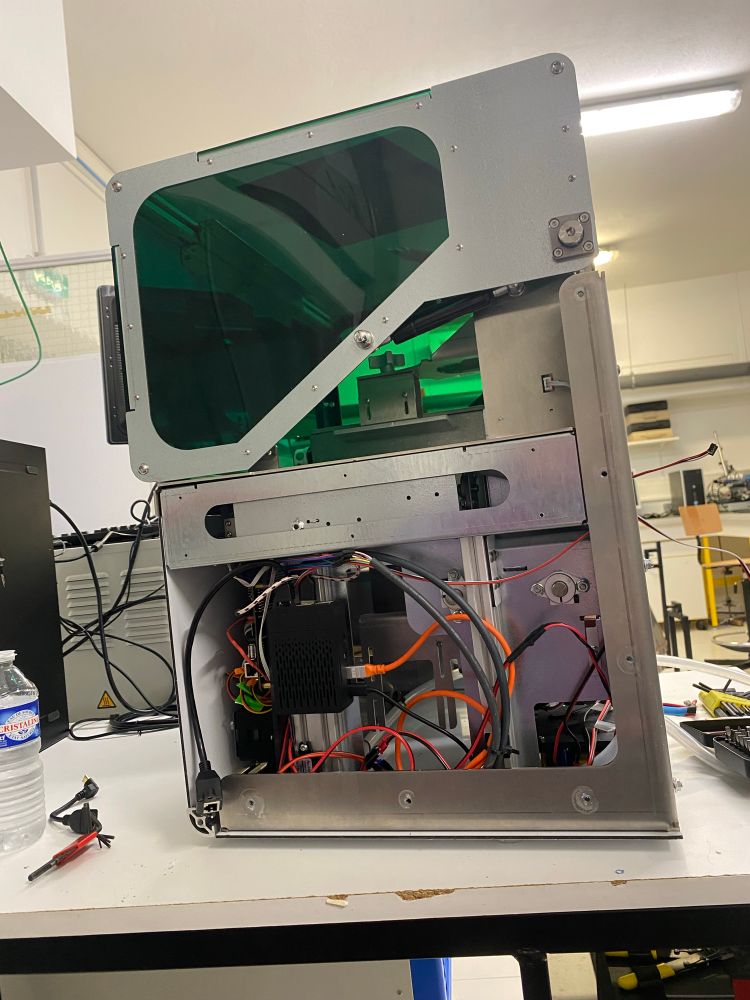

It’s been a while since we last posted, in part to manage all the orders have. We’re reaching a lovely point where we can build Sun-assemblies and once everything is wired together, it just works smoothly right from the get-go #manufacturing #3dprinting

31.10.2025 01:08 — 👍 2 🔁 0 💬 0 📌 0

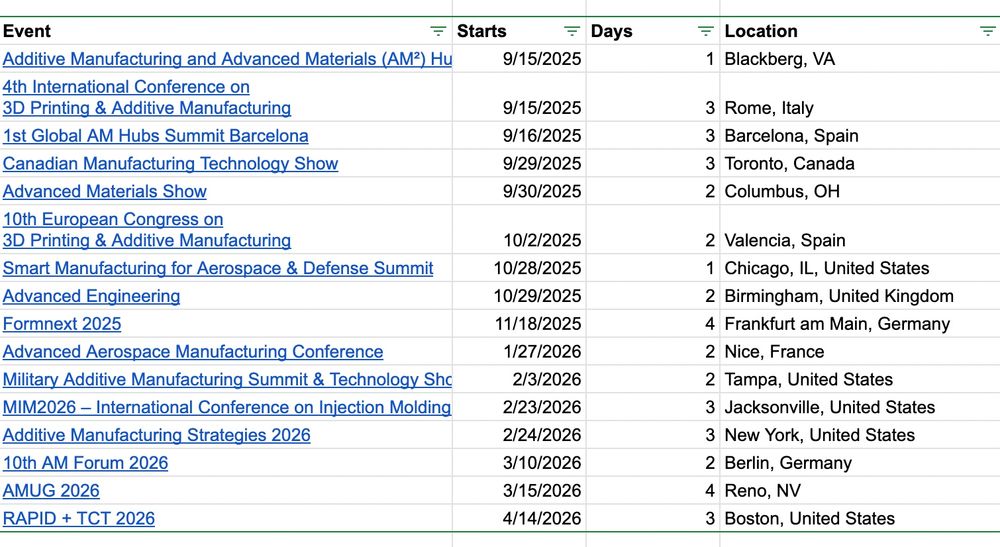

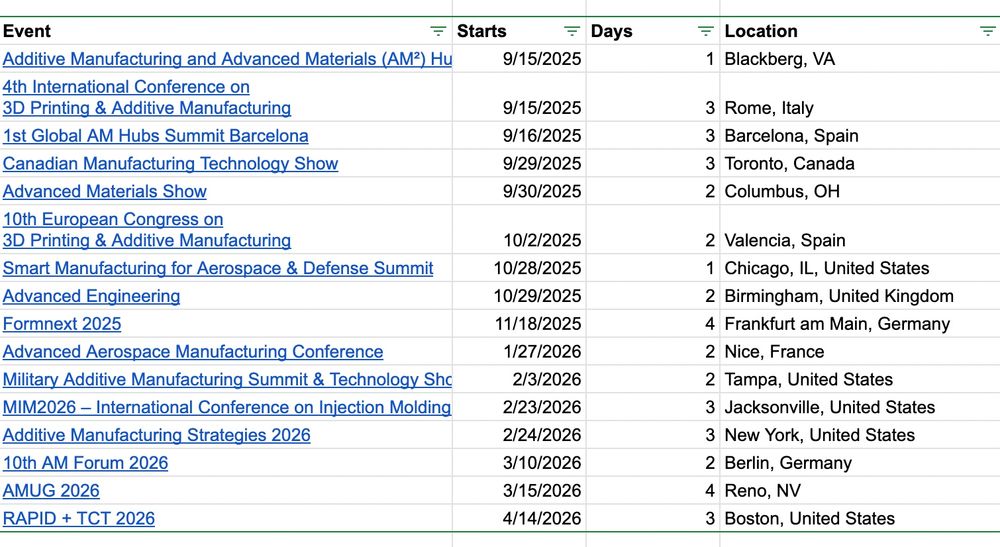

Dear 3D Printing Fanatics - which Trade shows should we go to? Any recommendations, or any missing (and why?)

30.07.2025 17:08 — 👍 2 🔁 0 💬 0 📌 0

Greetings from the CNRS lab in Toulouse, France :)

05.06.2025 22:14 — 👍 2 🔁 0 💬 0 📌 0

Duly noted

29.05.2025 02:10 — 👍 1 🔁 0 💬 0 📌 0

Good to know! For me, integrating electronics and other elements (flex, rigid, other materials) matters a lot, and even parts like chips and connectors.

This is the future imho - far more than just 3D printing, but total harmonious integration. That’s our vision

28.05.2025 13:58 — 👍 1 🔁 0 💬 1 📌 0

Yup - hard to improve on the essentials … but what makes a format useful is how many use it, not necessarily how good it is. Ex: VHS v Betamax

28.05.2025 13:46 — 👍 1 🔁 0 💬 1 📌 0

Heeey I used to work there before we got bought by Stratasys. I wrote a lot of the content and managed the competitions, etc

28.05.2025 13:27 — 👍 1 🔁 0 💬 2 📌 0

Yeah very helpful! But handling multiple files is a bit of a different story, or colors or functions. “Just Hit Print” gets more complicated … “more models, more problems” ;p

27.05.2025 20:02 — 👍 1 🔁 0 💬 1 📌 0

Yeah I like STEP as well but never considered it a AM format. I missed the memo on 3MF but recall AMFs big debut in the early 2010s

Should I include STEP and 3MF?

27.05.2025 19:15 — 👍 1 🔁 0 💬 1 📌 0

Is anyone still using STLs? Shimmy will still support them but for Multi-Material 3D Printing, processing them is painful. AMF is better but what other formats have become big hits for you?

27.05.2025 18:51 — 👍 2 🔁 0 💬 1 📌 0

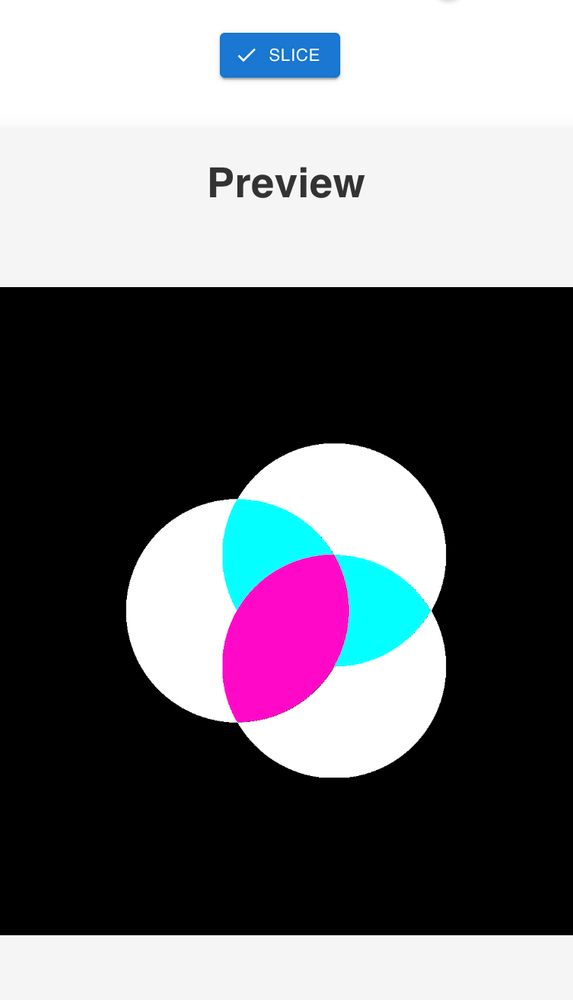

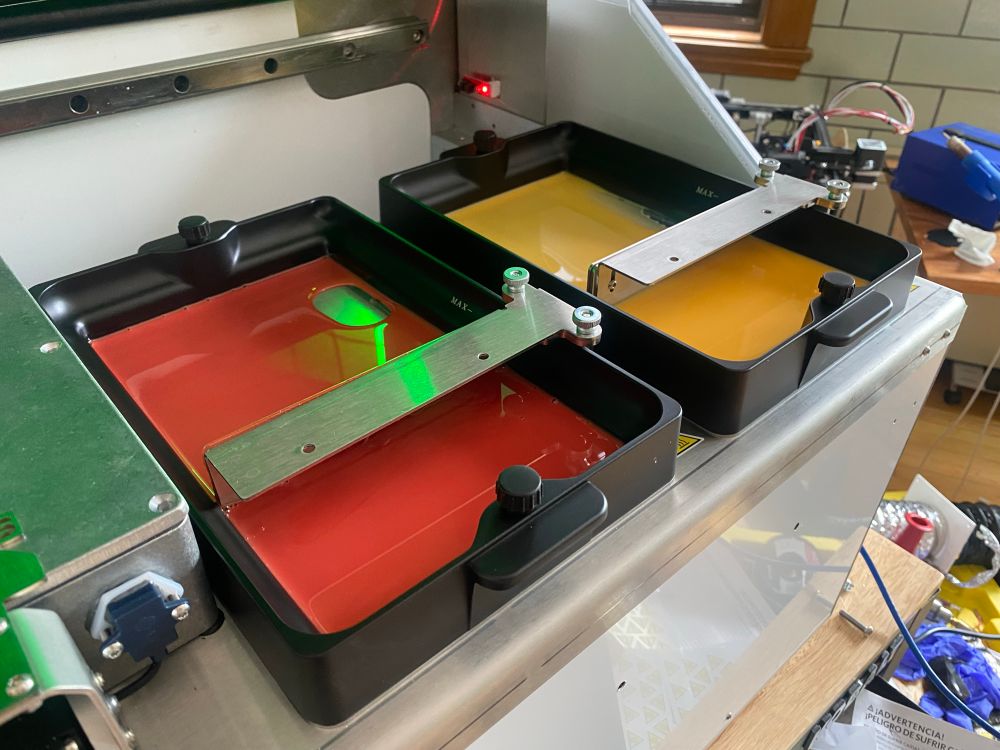

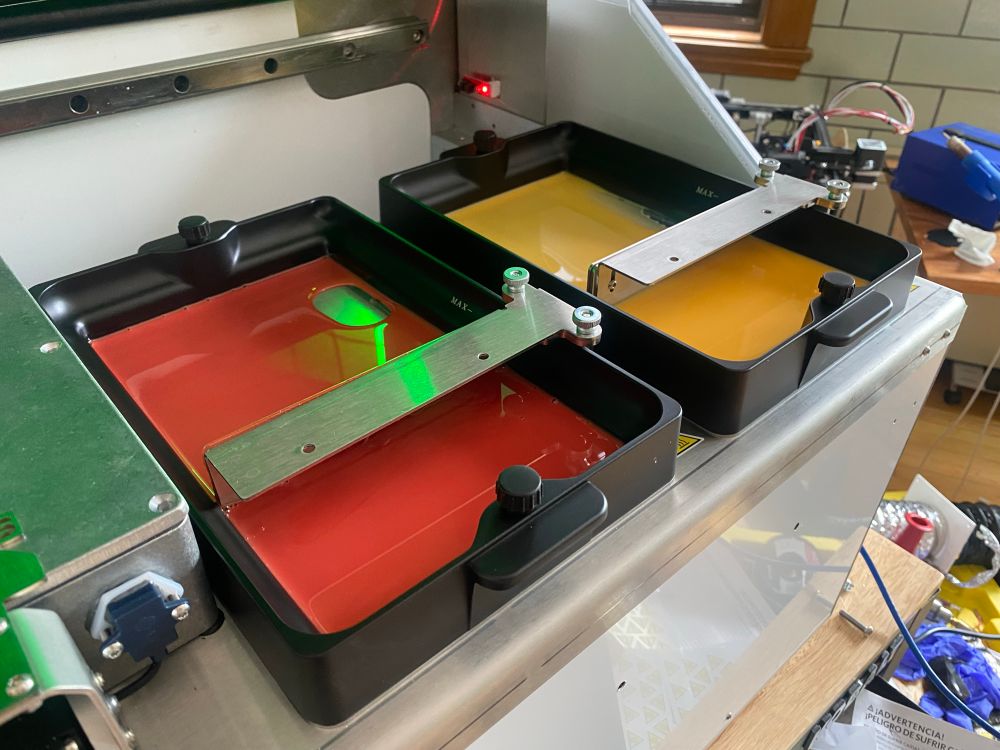

Very much like a hotdog with the ketchup/mustard colors (standing in for Magenta and Yellow). None of the vat Z heights or XY offsets were calibrated, but it didn’t fail either!

Just wanting in terms of color management! That’s for another day #color #3dprinting

23.05.2025 20:18 — 👍 4 🔁 0 💬 0 📌 0

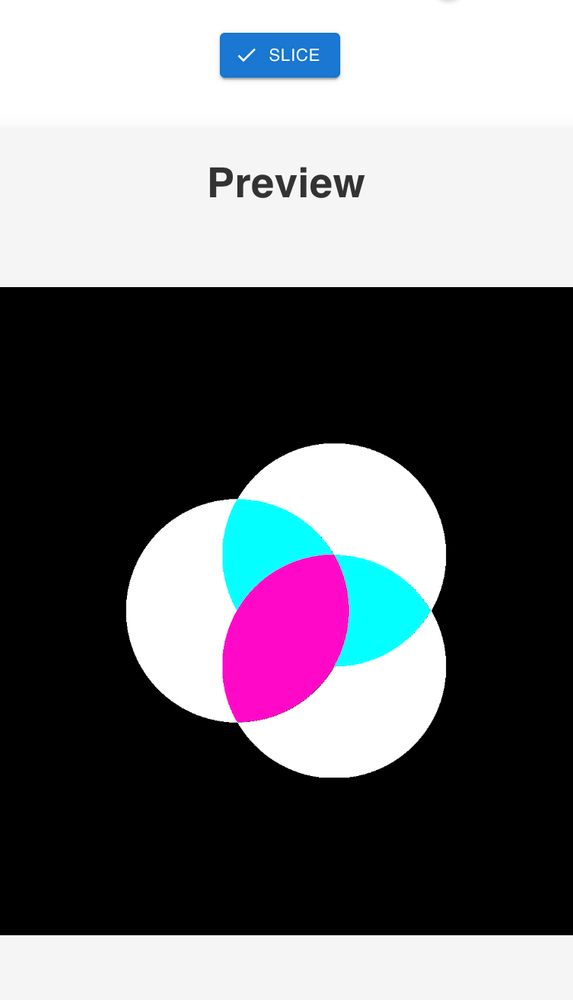

But here’s a preview - literally - to hint at what we’re testing. This was taken from our interface

23.05.2025 18:39 — 👍 0 🔁 0 💬 0 📌 0

Am 3D Printing with ketchup and mustard. Cannot provide advice on taste or texture - but I can tell you that yes, that is two of a four vat resin printer we built ;)

23.05.2025 18:33 — 👍 1 🔁 0 💬 1 📌 0

Your approach is certainly a hybrid like mine. You made the mask using a liquid resin (or film) then laser-ablated it, yeah?

22.05.2025 14:29 — 👍 0 🔁 0 💬 1 📌 0

Oh I’m talking about another printer prototype that print Copper + Cyclic Olefin Copolymer. We can even introduce fiberglass to match the CTE properties. Have also considered ceramics as well, which are easily printable as a substrate.

22.05.2025 14:27 — 👍 0 🔁 0 💬 0 📌 0

We have a prototype machine that works on a similar principal - same price but infinite layers and even bulk metal printing.

I’d love to share our experience and see what you’ve got.

22.05.2025 12:59 — 👍 0 🔁 0 💬 1 📌 0

Am assuming you’re using a laser? Maybe milling but i doubt it.

21.05.2025 20:11 — 👍 0 🔁 0 💬 1 📌 0

Not unreasonable, but decent PCB mills can do two layers for 1/3rd the cost. Iirc a BotFactory SV2 can do 4 layers or more for about the same price, plus pasting and assembly.

What they have issues with is the conductors are not copper, and the materials aren’t great.

What are your PCBs made of?

21.05.2025 13:17 — 👍 0 🔁 0 💬 1 📌 0

What’s the base cost for a machine that makes two layers?

21.05.2025 00:26 — 👍 0 🔁 0 💬 1 📌 0

I have worked in PCB Printing for desktops in past and present roles. It depends on what the final result is (ENIG pads? Copper thickness? Substrate?) … also is there a pathway to 4/6/8+ layers?

20.05.2025 00:56 — 👍 0 🔁 0 💬 1 📌 0

I’d be curious to know if you’re looking at soft and hard materials to be combined for your 3D prints… might be something we can print!

20.05.2025 00:53 — 👍 0 🔁 0 💬 0 📌 0

We may have a solution to your issue :)

20.05.2025 00:50 — 👍 0 🔁 0 💬 0 📌 0

We are a multimaterial 3d printing company and the CAD software exists. You can model virtually anything with almost CAD tools so idk what this person is talking about.

There is a field of “DfAM” or Design for Additive Mfg … and those tools don’t manage MM3DP well … yet!

20.05.2025 00:48 — 👍 0 🔁 0 💬 0 📌 0

What lies beneath a four vat 3D printer … hat tip to the temperature sensor and stepper wiring in their support roles

19.05.2025 19:15 — 👍 0 🔁 0 💬 0 📌 0

A small sample of the exciting stuff we have in the pipeline! If all goes well we can share everything we can do with our “Quad” resin vat 3D printer ;) #3dprinting #innovation #fourmorevats

19.05.2025 19:14 — 👍 1 🔁 0 💬 0 📌 0

I read a review of Neuromancer that described the world William Gibson made as “a place I’d like to visit, but not live in”.

What do you call that sort of Future?

16.05.2025 00:49 — 👍 3 🔁 0 💬 1 📌 0

pragmatic, progressive, multidisciplinary creative, data scientist & full stack dev. occasional avid beach goer. always learning.

🔗 https://marko.tech 🏠 https://startyparty.dev

Writer since the early eighties. 3D Model and game creator. Married to the novelist A L Norton. No DMS Unless I know you.

🔬 Assistant Prof, Pathology @Duke | Director, Clin Micro Lab

🧫 Former Clin Micro Fellow @Memorial Sloan Kettering

👩🏻🔬 Former Postdoc @broadinstitute.org

🎓 PhD @The Rockefeller University

Focus: Diagnostics, AMR, Structural Biology

Current software engineer, former theoretical physicist, permanently distracted

Artist designer polymer clay, 3D printing, 3D design, mixed media

Join a bleeding-heart liberal and compulsive speculator rambling about saving the world with win-win games at nonzerosum.games!

Interested in tech, video games, 3D printing, and creating along with releasing 3D models. YouTube www.youtube.com/@kalbo64

#3d #3dprint #3dprinter #3dprints #creality #stl #k1 #3dprinting

Your Friendly Expert Who Breaks Down 3D Printing Like Never Before 🚀

🌏 Want real-time 3D printing help and community?

Join our free private Discord here: keenmaker.kit.com/the-keen-maker-collective

❤️Support us: https://ko-fi.com/keenmaker

Impressora para Circuito impresso

Electronics & systems engineer, programmer, nerd.

Also spirit532@mastodon.social and @spirit532_ at the dumpster fire one.

Other socials and contact at https://spirit.re/

Anatomist. Digital anatomy at https://sketchfab.com/jplister and https://vimeo.com/user92177418.

Cybersecurity at Toyota, car enthusiast, soccer nut

The Laboratory Robotics Interest Group (LRIG) is the largest dues-free not-for-profit special interest group focused on laboratory automation. Visit us at https://www.lrig.org/

#LRIG #LabAutomation #LaboratoryAutomation #LaboratoryRobotics #LabRobotics

Futurist, veteran cricketer, board gamer, venture philanthropist. Strong views weakly held (not always successfully), ageing not so gracefully

is a scientific artist, micro-CT professional, and interested in the intersection of art, science, and technology. https://linktr.ee/AINeander

Technology reporter, analyst and Editor-in-chief at 3D Printing Industry. Author. Additive manufacturing, sci-fi.

Dare mighty things! Journeyman wondersmith at Speculative Technologies. 🏴☠️🪐🐉

https://Benjaminreinhardt.com + https://spec.tech

He/Him, Back to the Future expert for podcasts, reliably reposting.

Do not talk to me about Crypto, NFTs, AI, or investing, I am not your guy. The Block will be instant and my regrets zero.