The Gloink rolls! All will be Gloink!

21.07.2025 18:10 — 👍 0 🔁 0 💬 0 📌 0Thinkulator

@thinkulator.com.bsky.social

Bringing excel-style formulas to the IoT Edge https://thinkulator.com Bootstrapping in public. Wanna come along for the ride?

@thinkulator.com.bsky.social

Bringing excel-style formulas to the IoT Edge https://thinkulator.com Bootstrapping in public. Wanna come along for the ride?

The Gloink rolls! All will be Gloink!

21.07.2025 18:10 — 👍 0 🔁 0 💬 0 📌 0

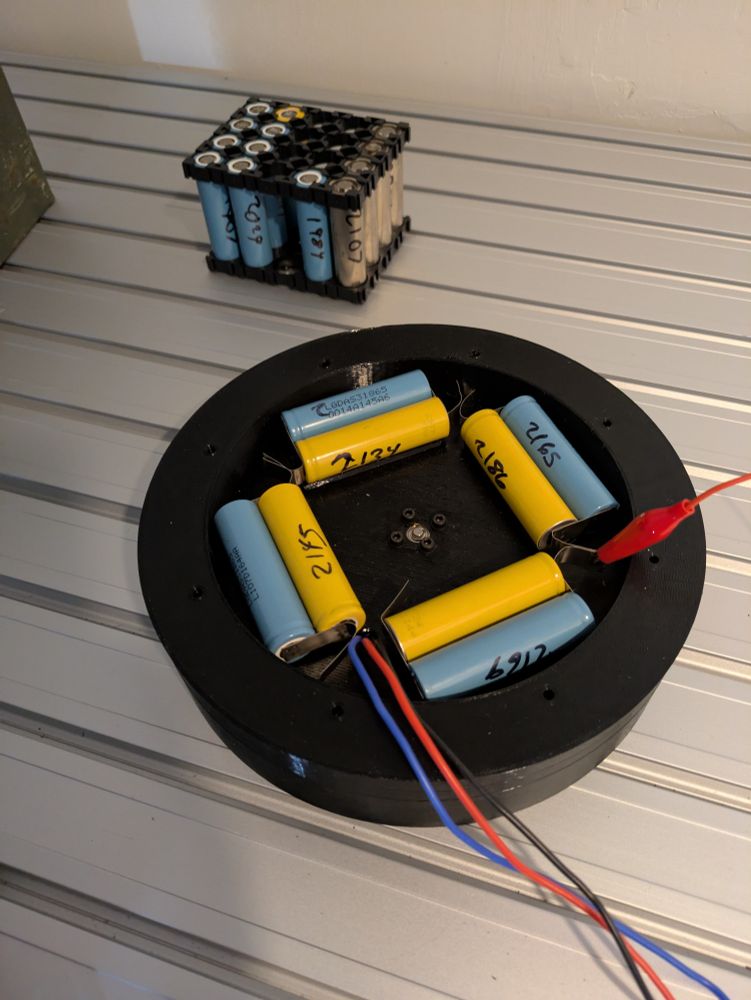

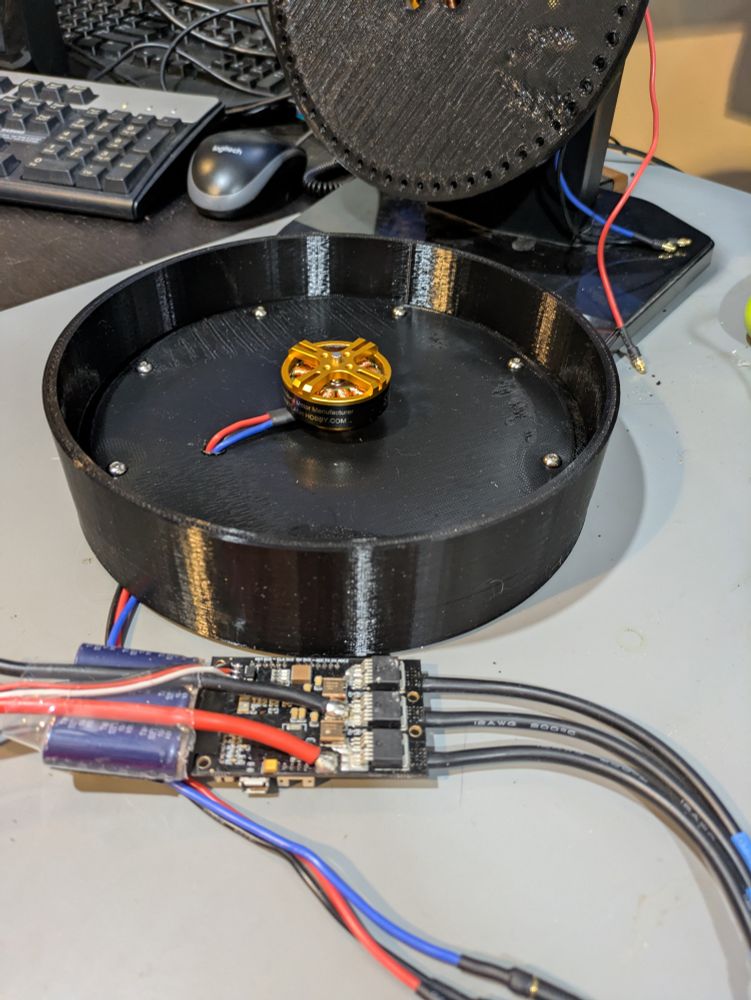

Custom battery pack for the Gloink, and make-do wiring, to do some testing and initial measurements.

19.07.2025 22:17 — 👍 1 🔁 1 💬 0 📌 0Thinkulator Dynamic let you embed intelligence directly into your products. Solve integration issues without PLC programming or embedded systems code.

09.07.2025 20:38 — 👍 1 🔁 0 💬 0 📌 0Looking to enable AI based configuration of smart devices and sensors?

AI agents can generate programs, but often fail when working in the embedded space. Our technology enables LLM created logic, to be deployed to edge devices, in realtime, by customers.

Custom configurations in seconds.

In a saturated space, how can your products stand out?

Dynamic enables your product to run logic defined by the end-user, using a familiar language. This often eliminates the need for external PLCs, giving your customers unprecedented control and you a competitive edge.

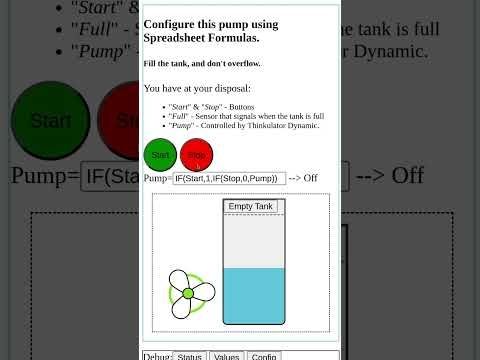

Want to see how Dynamic makes configuring devices with custom logic, super easy?

This video is captured from our upcoming digital twin based training system, and uses an emulated ARM Thumb micro internally.

It runs the same on real hardware, only faster :)

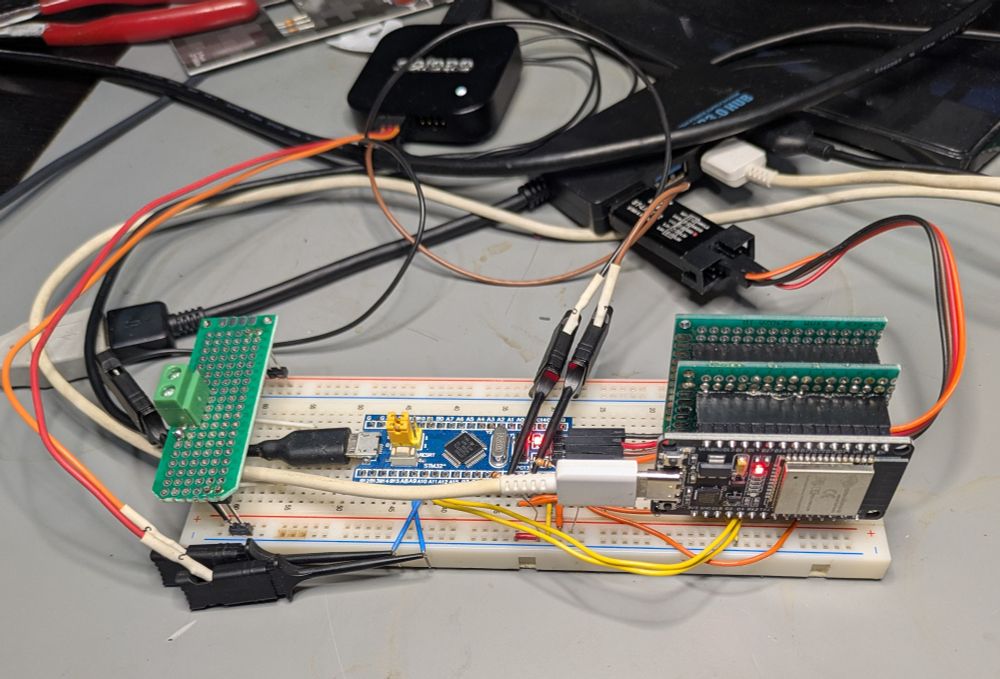

And I'd be a little ashamed to show you the back side of the tombstone that esp32 board is attached to.

01.07.2025 01:37 — 👍 1 🔁 0 💬 1 📌 0Sigh, yea it does. This was just to get the i2c and serial connections up, so I could bootstrap the communications code.

01.07.2025 01:35 — 👍 0 🔁 0 💬 1 📌 0

Breadboard with an STM32 blue pill, and an ESP32-Wroom de board. There is a mess of wires, a logic analyzer, and other devices in frame.

The mess before the PCB gets spun is always the worst.

30.06.2025 21:45 — 👍 5 🔁 0 💬 1 📌 0Had a great mentorship discussion w/ a former coworker, who does startup guidance.

We really honed in on how my messaging needs to change, and what the real problems my tools are targeting.

That said: My brain never stops thinking about improvements and next steps, and I still had a few networking meetings.

20.06.2025 20:35 — 👍 0 🔁 0 💬 0 📌 0I've been taking the week off for some family time. We did some axe throwing, and skill building.

It's amazing how much overlap there is between helping mentor people professionally and teaching your kids life skills.

This one was especially about the importance of celebrating our successes.

This past week was spent on some backend business tasks. Presentations, technical documentation, architecture overviews, and a few quarterly business reviews.

Plus a side-quest to keep my parts bins organized while being transported.

It was nice to reflect on the progress I've made.

Try, test, change, and play, quickly and easily.

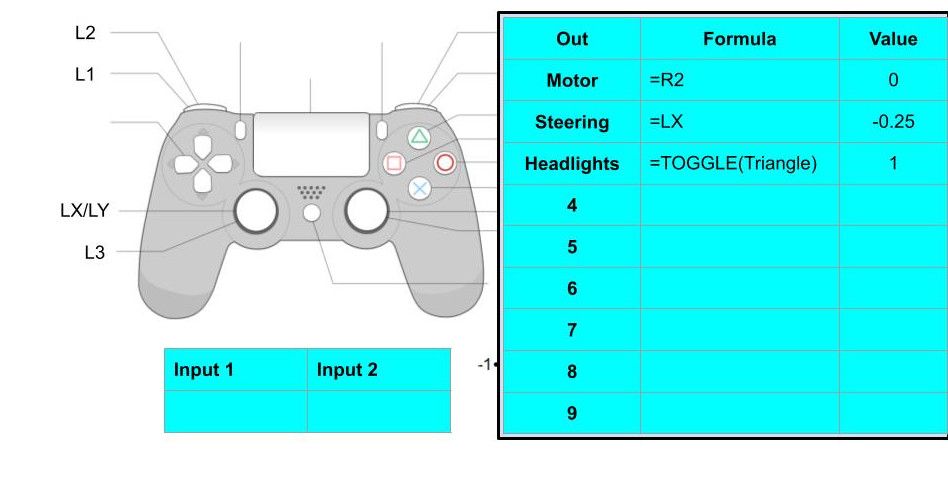

Dynamic RC uses short formulas to map gamepad buttons to control servos, relays and lights in your Remote Control projects.

Want to change something? They're working in less than a second, no reboots.

Yes! Pretty much any gamepad that uses bluetooth should work.

04.06.2025 15:50 — 👍 1 🔁 0 💬 0 📌 0

We made the mock UI for configuring Dynamic RC!

It shows how you map buttons to channels, this one is using our method to make spreadsheet-style formulas that run on-device.

Any ideas for other ways to map buttons to servos, motors, relays we could try out?

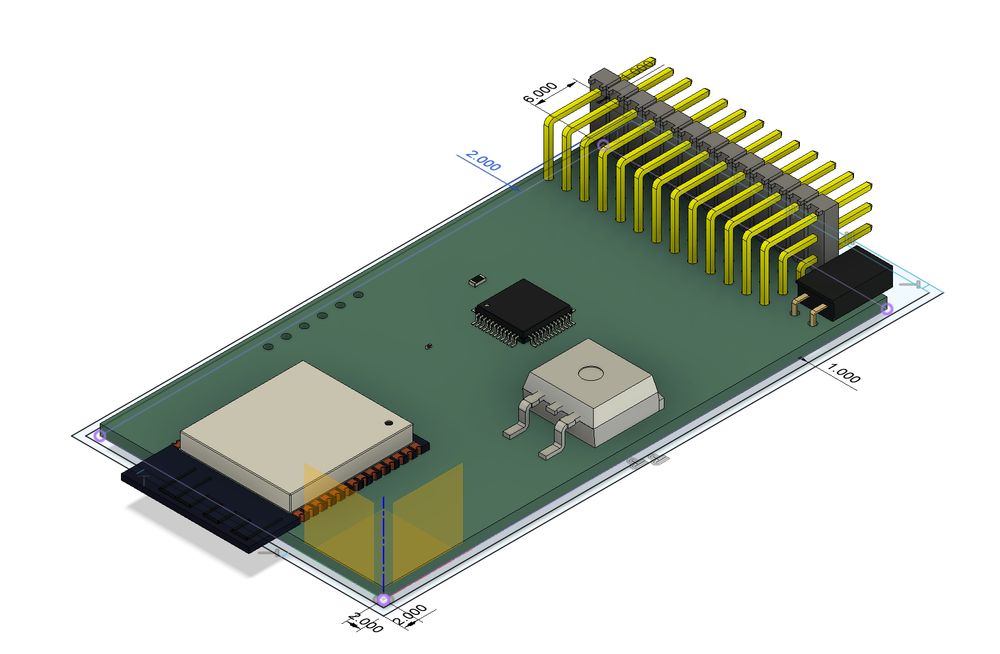

Mechanical design in-progress for Dynamic RC. 10 channels, two inputs, and programmable button mappings for your Bluetooth gamepad.

Our goal is to make including servos, relays and lights, SUPER easy. We built tools that make it quick and easy to configure, with lots of flexibility.

Testing the CNC controls for the first time. Starting with the pulse generator, axis selection and homing.

Each button press or dial change sends Gcode to the CNC controller.

I've made a large amount of progress, but formally writing up my successes? That feels weird.

Writing updates is one of the least-fun parts of trying to launch something.

A shop-built CNC control panel, with a dial and display on the far left, to the right is two panels of 3x5 buttons with custom labels. You can see letters signifying axis on some, and length increment on others. Further right from this is an abort button and am estop switch.

I love the control panel I made for my DIY CNC. Each cherry MX switch sends the Gcode directly into the CNC controller, and shows status and toggles.

It was really fun to design and build this configurable panel setup, based around Eurorack rails.

The Gloink build progresses! I have some testing and experiments to run on controlling the reaction wheel. This is a quick testbed for that!

Soon, all will be Gloink!

Story time!

One of my favorite activities when in a new country, is learning little phrases in the local language. I always start with "please", and "thank you".

That smile you get from someone, when you show you have put in the effort.

Especially, as someone from the USA.

Whoooo, last week was quite the week. Wasn't it?

21.04.2025 03:05 — 👍 0 🔁 0 💬 0 📌 0Today was a coaching and collaboration day:

* Intro call w/ a local entrepreneurship non-profit.

* A peer discussion with another startup founder in manufacturing tech - through a good friend.

Good things to think about. Plus, it's fun to practice the pitch and hear others give theirs!

I follow this approach. Code should be relatively self-documenting on what it does.

Why it does it that way, is what comments and commit log messages are for.

I will get my flame-suit ready for this one. <3

09.04.2025 21:23 — 👍 0 🔁 0 💬 0 📌 0Spent a chunk of today doing accounting and other such stuff, but also got our main website up and running finally.

It's short and simple on purpose. But I would love feedback from anyone who has it!

Explanations for the tech itself are incoming, but I wanted to get something up to start with.

That's always a tough one for me too, especially when I have not been able to find the spoons to work on something I used to enjoy.

At least for me, it's because I am either overwhelmed with life stuff, or I'm at a frustrating part of the build.

Checking in, how'd you do working on your art projects?

What kind of progress have you made this past month? (Even if it's just thinking about stuff you want to do next, or how to solve the current problem)

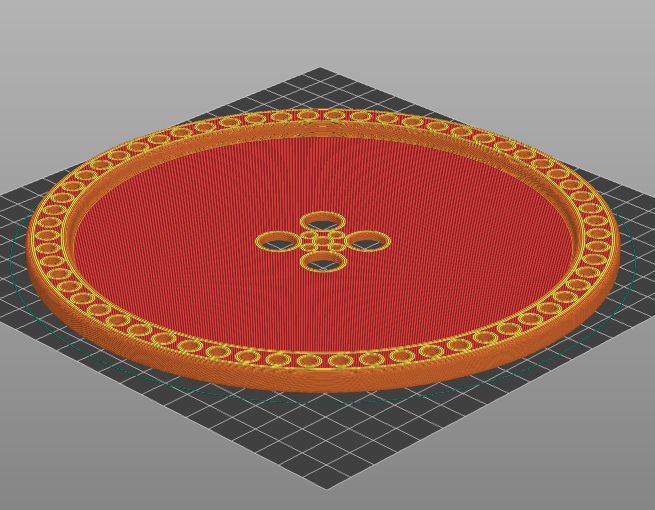

A screenshot of Prusaslicer, which has a round flat object, with 60 holes at the edges, four larger holes in the center, and four smaller holes closer to the center pivot point. It looks like a reaction wheel which would be used on a spacecraft.

A yellow-colored cylinder, showing a "Circle Gloink" from Glitch's show "Amazing Digital Circus", It has two eyes of substantially different sizes, and a "mouth" - meant to convey that it is "alive"

Today's project is a prototype reaction wheel for our "Gloink" build. We'll make the real one w/ metal in the future. The holes are for M5 bolts to vary the mass.

Using a BLDC motor, with this print, to figure out the control formulas. Then to figure out motion and steering.